Polycaprolactone (PCL) is a biodegradable polyester with a wide range of applications in the medical field, biomaterials, and 3D printing. While PCL powder and PCL microspheres are both derived from this versatile material, they differ significantly in form, preparation methods, and application areas. This article delves into these differences to provide a clearer understanding of how each form of PCL is used in various industries.

Form and Physical Characteristics

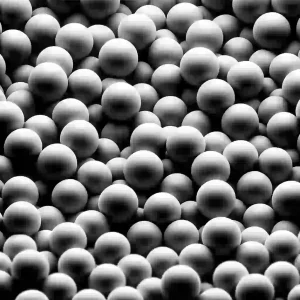

- PCL Powder: This form of PCL is essentially PCL in powder state, characterized by larger, irregularly shaped particles. It is directly utilized in several processing techniques, such as blending, compression molding, or as a raw material for 3D printing processes. The powder form is advantageous for applications requiring bulk material processing or where the material’s flow properties are critical.

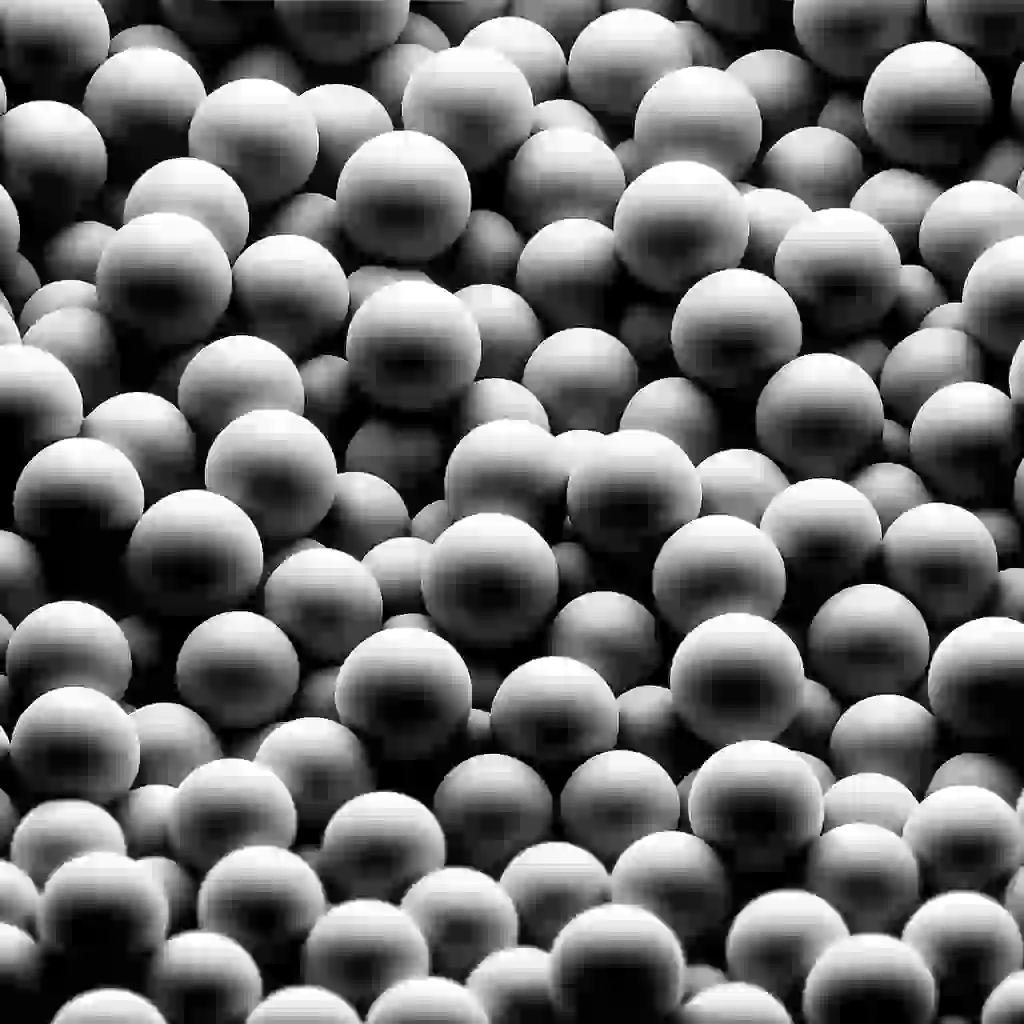

- PCL Microspheres: In contrast, PCL microspheres are tiny, spherical particles of PCL, boasting uniform size and shape. The production of PCL microspheres involves more sophisticated techniques, such as emulsion, solvent evaporation, or phase separation methods. These microspheres are designed for precision applications, including drug delivery systems, tissue engineering scaffolds, and cosmetic products, where controlled release and high surface area are beneficial.

Preparation Methods

The preparation of PCL powder is relatively straightforward. It can be produced by physically grinding PCL bulk material or through chemical synthesis methods that yield the polymer in powder form. This simplicity in production makes PCL powder a versatile and accessible material for a wide range of applications.

On the other hand, creating PCL microspheres requires advanced technological processes. Techniques like emulsion-solvent evaporation and phase separation allow for meticulous control over the microspheres’ size, shape, and surface characteristics. These methods cater to specific application needs, particularly in the biomedical field, where precision and biocompatibility are paramount.

Application Areas

- PCL Powder Applications: The larger particle size and irregular shape of PCL powder make it suitable for 3D printing materials, composite material preparation, and the manufacturing of medical devices. Its ease of processing and compatibility with various manufacturing techniques have made it a staple in these industries.

- PCL Microspheres Applications: The controlled particle size and high surface area of PCL microspheres make them ideal for use as drug delivery carriers, cellular carriers in tissue engineering, and fillers in cosmetic formulations. Their ability to provide sustained release of active ingredients and to support cell growth and proliferation are particularly valued in the pharmaceutical and biomedical sectors.

Conclusion

Both PCL powder and PCL microspheres offer unique advantages based on their physical characteristics, preparation methods, and application areas. While PCL powder is favored for its versatility and ease of use in bulk processing applications, PCL microspheres are preferred in applications requiring precision, controlled release, and high biocompatibility. The choice between PCL powder and PCL microspheres ultimately depends on the specific requirements of the application at hand. Understanding these differences is crucial for researchers, engineers, and manufacturers in selecting the appropriate form of PCL for their needs, ensuring the success of their projects and innovations in various fields.